Integrated management for made-to-order production with control, efficiency and traceability.

Home » Automotive sector

The automotive industry is undergoing a profound transformation: electrification, digitalization, regulatory requirements, pressure for innovation and sustainability. It's a sector where every second of downtime directly impacts productivity and global competitiveness. To overcome these challenges, companies need complete visibility of their operations and precise control over every stage of the production process.

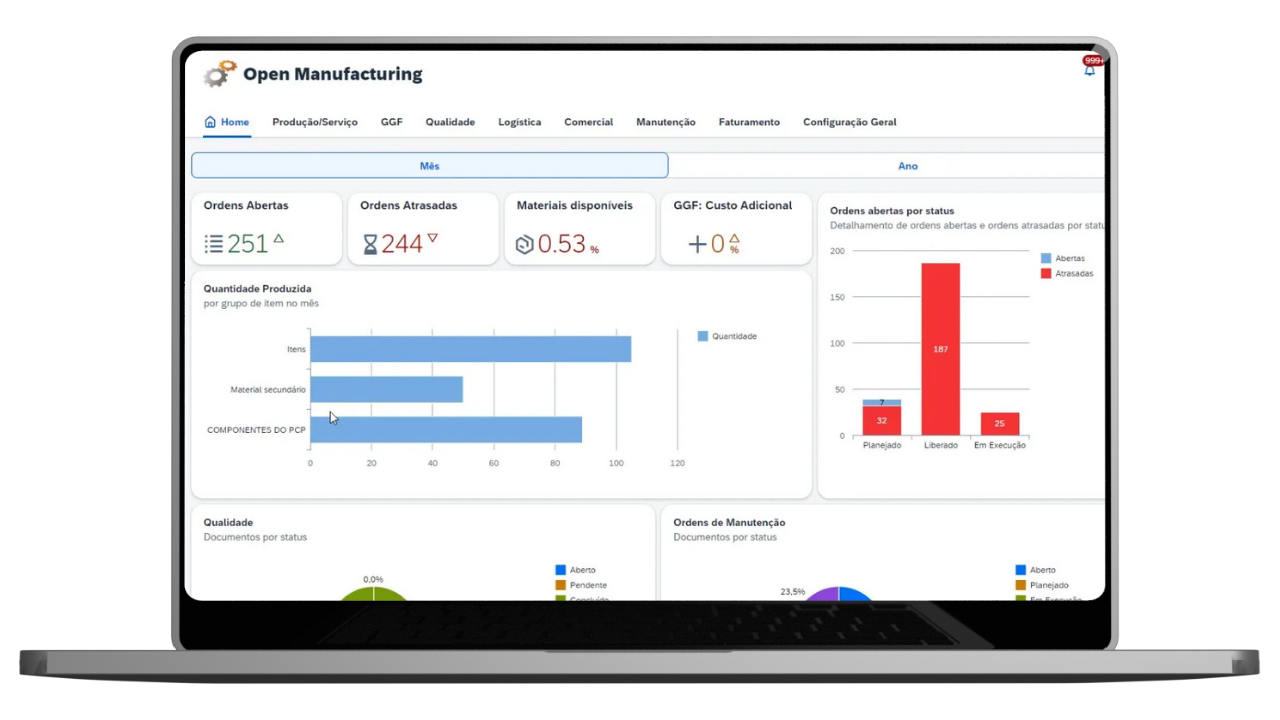

Open Manufacturing integrates management and the factory floor. It provides specialized services to meet the demands of automakers and suppliers in the automotive supply chain, ensuring high operational efficiency, complete traceability of production processes, and agility in decision-making.

High dependence on multiple suppliers, lack of real-time visibility, and constant risk of delays in critical inputs, compromising delivery deadlines, production, and costs.

OPEN Manufacturing connects production, inventory, and supplier areas in real time, offering complete supply chain visibility. This enables predictability, risk anticipation, and efficient planning, reducing delays and increasing operational reliability.

The simultaneous assembly of different models and versions requires high flexibility, precise synchronization, and rigorous control of variables, otherwise there is a risk of rework, waste, and loss of productivity.

Real-time production monitoring, complete component traceability, and dynamic line adjustments allow for maintaining efficiency and quality, even in highly complex and customized production environments.

Meeting international safety and quality standards requires absolute control over processes and components. Failures can result in recalls, financial losses, and damage to brand reputation.

Open Manufacturing enables integrated digital inspections, automated records, and complete traceability of critical components, ensuring continuous compliance, reduced non-conformities, and proactive support for audits and regulatory requirements.

The lack of integration between systems and the lack of immediate visibility into operations on the factory floor hinder agile decision-making, increase rework, and compromise quality and productivity.

OPEN Manufacturing enables real-time visibility, integration between production, logistics, and quality, and complete traceability control. It reduces bottlenecks and downtime with up-to-date data directly from the factory floor.

It improves decision-making with accurate and centralized information.

It increases productivity and ensures compliance with the high standards of the automotive industry.

This website uses cookies to improve your experience. By clicking "Got it" you agree to the Privacy Policy from the website.